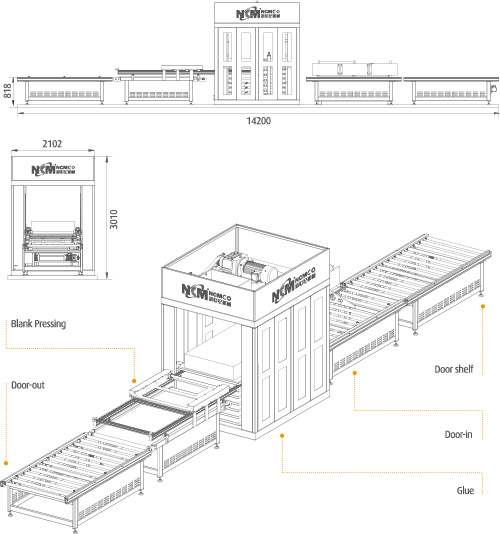

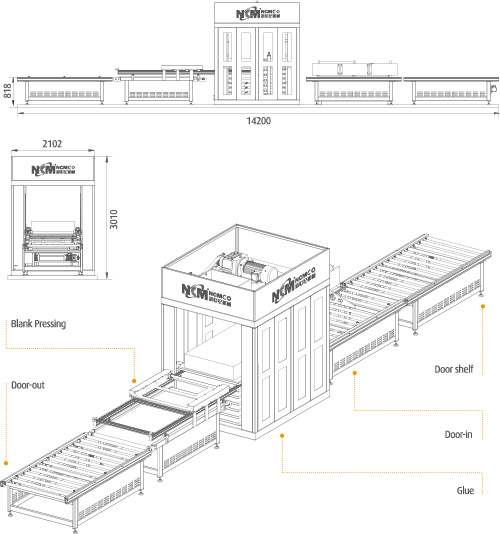

The Machine Function

The gluing machine composed of several hot pressing plates for pressing and heating each group of pressing plates. It is the most widely used door gluing engine. Its full name is itelligent flow hot - press gluing machine. It is to put the door slab into the filer with the plate loading machine into the multi-layer hot press, heating and pressure at the same time, the slab pressing the finished door fan, according to the mode of operation is divided into two types of periodic and continuous, the commonly used in China is the periodic muli-layer hot press. The hot press is composed of three parts: the hot press body, the control drive part and the heating system. Itelligent single-piece flow hot pressing gluing machine, including feeding roller conveying, guide conveying door device, hot pressing gluing main engine, positioning conveying edge holding device and out conveying device.

Production Proceed

Conveying→gluing→blank pressing

Good Stability

Multlayer large plane steel plate supeposition way of gluing. sabilily will be partir. ularly good. DO not wory about the defomatin of the door gluing, it is the best choice of hol gluing.

Good Heating Performance

Each layer of large plane sleel mesh ho water crculation with extemnal insulation layer, 50 that the heat uniform and stable efet is good.

Low Energy Consumption

Al drives adopt frequency conversion, rsistance wie heatig, low price, low cost and widely used.

Gl And Edge Performance

Door enterprises fit sprayed and glued, then door plate was hot pessing glued,and then use hyraulic overall edge pressing. Edge pressing in steel when it has temperalure, because it can reduces paint surface damage or breakage.

Easy Clean/ Maintain

Each layer ol plywood, the belly inletl 304 miror sainles seel high wearrsistance, And do not need to spend too much energy to maintain or dean the adhesive residue.

High Cost Performance

As the raw material of the multilayer hot pressing gluing machine adopts steel plate structure, it has a large weight dfference compared with the material used in the rller tpe gluing machine on the market.

Simple installation

Adhesion/thermal energy integrated machine, istallation does∩ot need to hit the kee, as long as the leveling is good. Generaly speaking, a few hours to debug the equipment, mobile position is convenient and fast.

Process Chart