Equipment Usage

Used for one-time stamping of locking holes, hinge holes, installation holes, and corner cutting holes for various steel and stainless steel door frames, front and rear door panels, such as anti-theft doors, fire doors, medical doors, and purification doors.

Principles of homework

After starting up, program presets are made according to the hole position combination requirements. After presets are completed, the door frame/door panel is loaded. After fixation, foot stamping is performed to achieve one-time molding of all hole positions/cutting angles.

Product features

● Integrated stamping can complete all hole positions and section forming in one go, with fast production efficiency;

● Fixed combination can effectively avoid errors in hole spacing caused by human factors;

● Independent punching, independent control, on-demand combination, wide applicability;

technical parameter

|

technical parameter

|

Reference indicators

|

|

Maximum output force of the main oil cylinder

|

150KN

|

|

Rated pressure value of hydraulic system

|

25MPA

|

|

Stamping station

|

(2-7)Workstation, customized according to customer needs

|

|

Workbench size

|

Customized according to mold size

|

|

Total power

|

7.5/11kw,Depending on the workstation

|

Detail display

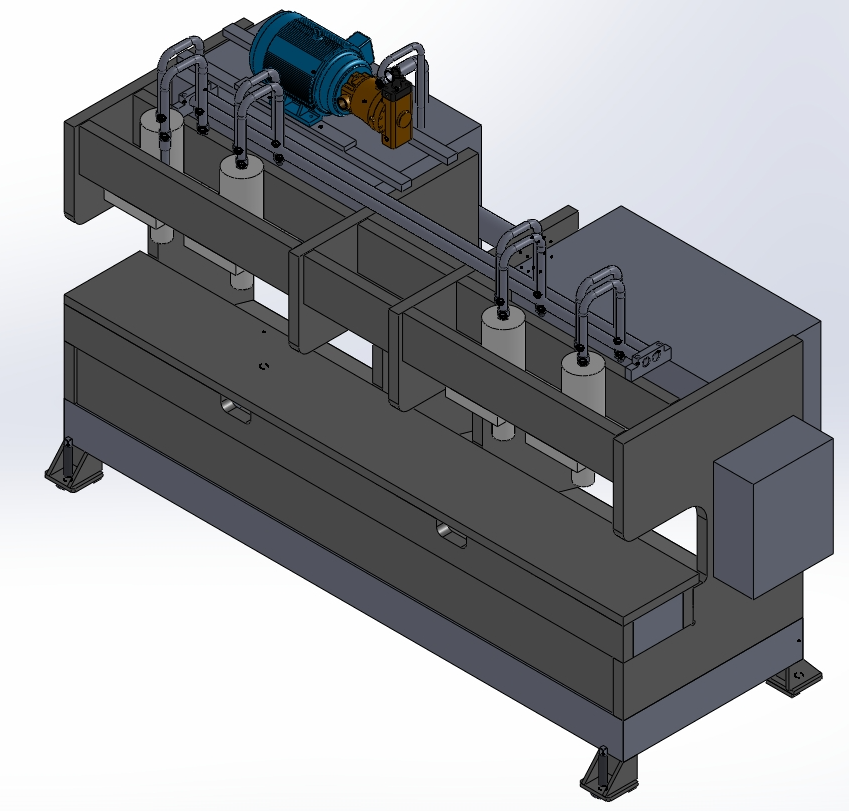

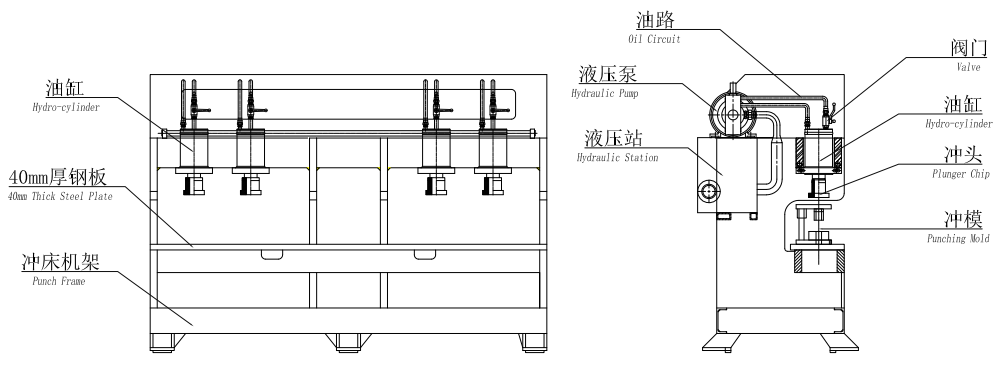

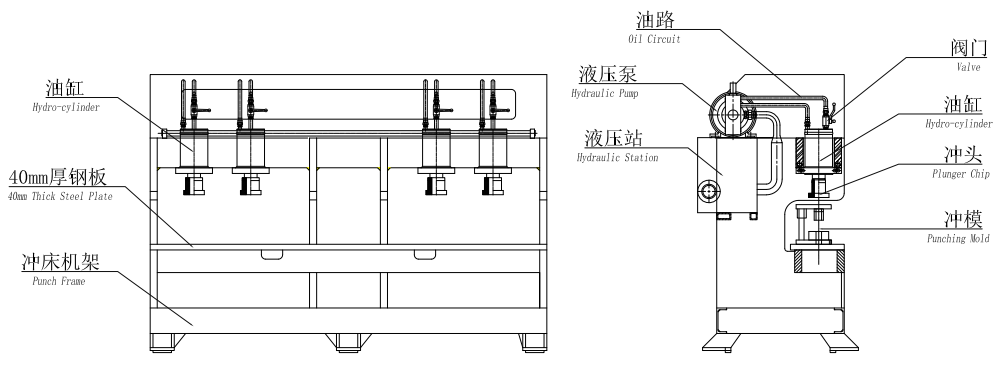

1. Host rack: The main structure of the device, which is the backbone of the device

● Through finite element analysis, the deformation trend of the machine tool under working conditions is analyzed to guide the design of a reasonable bed structure, ensure the consistency of the mold working center, and improve the accuracy of the parts;

2. Stamping device: power output for stamping

● The stamping method adopts hydraulic pressure, with greater force and no burrs on the stamping surface;

● Adopting an independent workstation and independent oil cylinder structure, each workstation can be independently controlled and can be combined for stamping as needed. At the same time, the independent oil cylinder ensures that if one oil cylinder is damaged in the future, it will not affect the use of other workstations;

● Each hydraulic component adopts imported or domestic first tier brand products, which are durable and long-lasting;

3. Punching mold: A mold for forming holes, which can be customized according to needs

● The punching molds are all made of Cr12Mov material, which is quenched and then processed by wire cutting, making them durable and long-lasting;

● The punching mold is easy to disassemble and assemble, making it convenient for subsequent on-demand mold replacement;

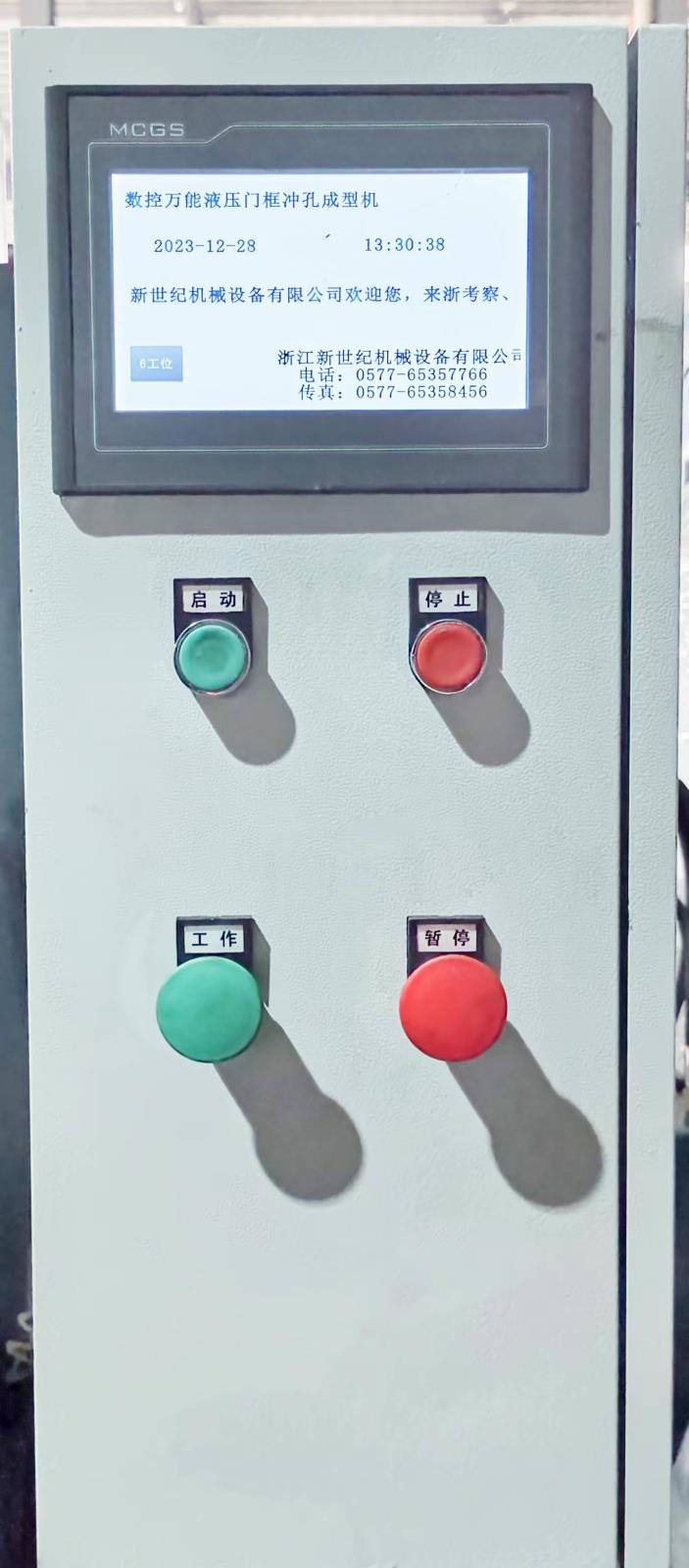

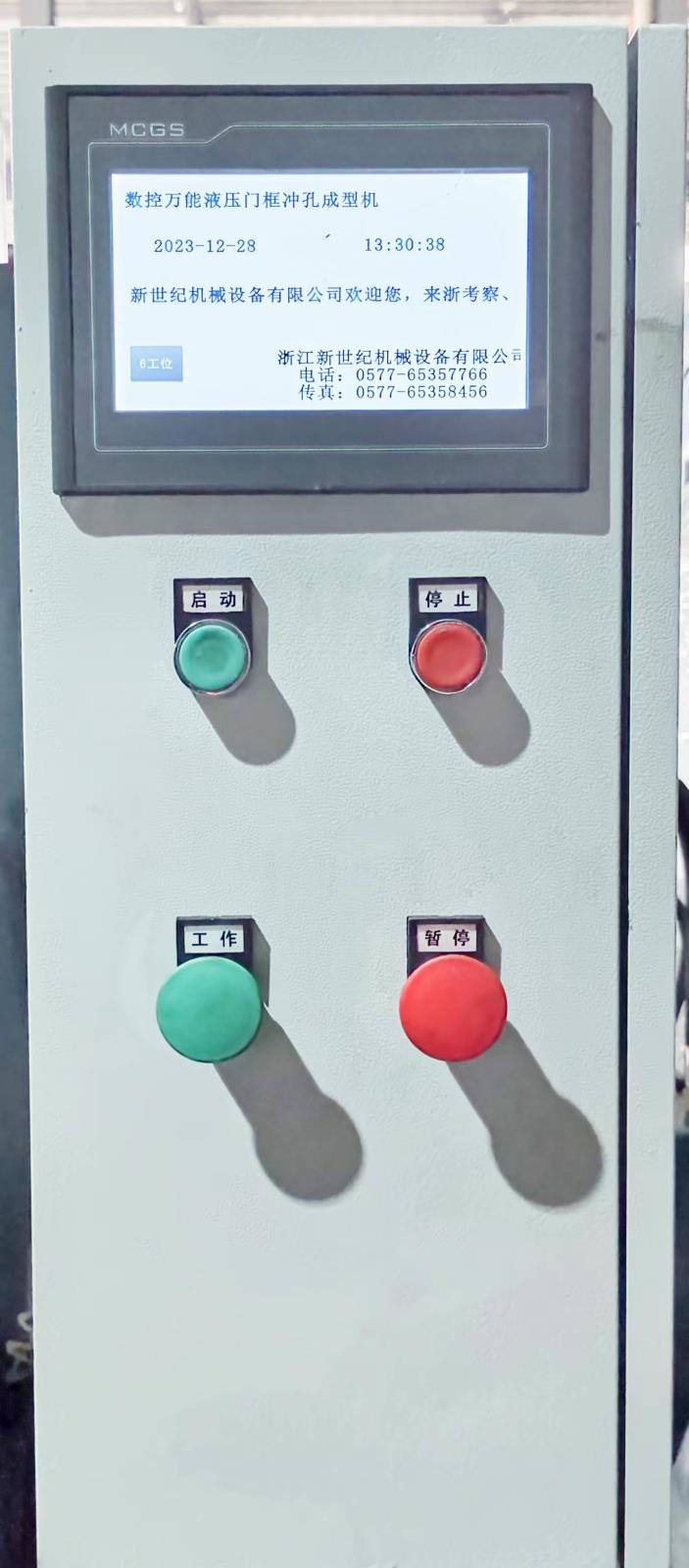

4. Electronic control system: The device control system is the brain of the device

● Adopting a PLC control system, the stamping station can be customized. After setting up, it can be achieved through foot or button pressing, achieving integrated stamping with flexible operation and low skill requirements for workers;

Random data

|

Number

|

name

|

quantity

|

Remarks

|

|

1

|

Shipping List

|

1 copy

|

|

|

2

|

Acceptance report

|

1 copy

|

|

|

3

|

User manual

|

1 set

|

|

|

4

|

Electrical schematic diagram

|

1 set

|

|

The cooperation that the user should provide

1. Power supply: 380V, 50HZ, voltage fluctuation range from -5% to+10%; When there is a significant fluctuation in voltage, users must be equipped with a voltage regulator, otherwise it will cause low-voltage electrical appliances to be in an abnormal working state, reduce or damage the service life of electrical components, scrap processed products, motor alarm causing shutdown, computer hard disk damage, and other problems.

2. Gas source: Output 0.6Mpa or above, dry and clean compressed air, with a supply rate of 0.3 cubic meters per minute; If the air dryness is not sufficient, users should be equipped with a refrigerated dryer, otherwise there may be problems such as water ingress into the pneumatic components causing increased piston friction resistance, wear of the sealing ring leading to air leakage, especially in winter, which is prone to icing and exacerbates damage to the pneumatic components.

3. Environmental temperature: 0 ° C to+40 ° C; Below 0 ° C, it can cause components such as oil-water separators and air tanks that may contain water to freeze. Lubricating oil becomes too viscous due to low temperature, affecting lubrication effectiveness and leading to component damage or failure.

4. Environmental humidity: Relative humidity of 20-80% RH (non condensing).

5. Stay away from strong vibration sources and electromagnetic interference; If the distance is too close, the user must be equipped with a filter, otherwise it may cause problems such as computer screen flickering, LED flashing, driver alarm, encoder abnormality, or interference with other nearby devices.

6. An environment with little dust and no harmful or corrosive gases.

7. Do not cut off power while the equipment is in operation and maintain voltage stability.